Author: Carla Berrospe-Rodriguez

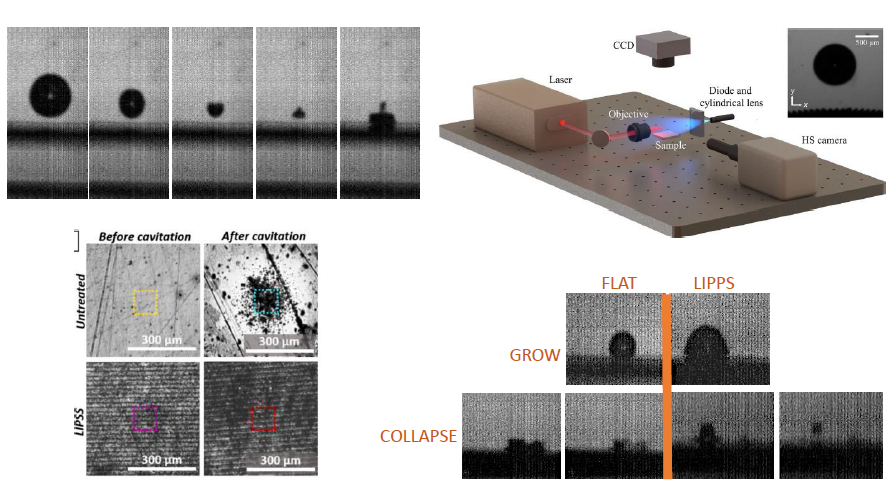

Laser-induced cavitation is produced when a high energy laser pulse is focused into a liquid medium leading to optical breakdown and consequently the formation of plasma by means of avalanche ionization. Plasma is short lived and undergoes a rapid radial thermal expansion at supersonic speeds, emitting a shockwave and vaporizing the surrounding parcel of fluid into the formation of a vapor bubble which rapidly grows and collapses. The dynamics of cavitation bubbles close to flat and rigid surfaces has been thoroughly studied mainly focused in understanding how to reduce damage in nautical equipment. The effects of solid boundaries can be generally understood as attracting a cavitation bubble and forming a microjet centered in a toroidal-shaped collapse (see Figure 4.1a). These studies later expanded to other types of boundaries including edges, parallel walls, enclosed microfluidics and furthermore to elastic surfaces. Additional nearby interfaces will complicate the cavitation dynamics but may enhance the efficiency for which cavitation has found applications in such as for microfluidics, or potentially surface cooling.

Figure 4.1. a) Dynamics of the cavitation bubble collapse close to a rigid boundary. b) Optical set up to study bubble dynamics close to a periodic elastic surface. c) Erosion produced by multiple cavitation bubbles in a flat BRASS sample and BRASS with LIPPS, respectively. d) Difference on the growth, collapse and rebounds of the bubble between a stainless-steel flat surface and with LIPSS.

Recently, S. R. Gonzalez Avila et al., demonstrated that biomimetic gas entrapping microtextured surfaces (GEMS) can repel cavitation bubbles and potentially reduce erosion. However, this kind of surface modification requires fabrication via molecular vapor deposition. Contrariwise, Laser Induced Periodic Surface Structures (LIPSS) have been shown to be a straightforward method to obtain nano and micro texturing. The generation of LIPSS requires irradiation of a solid with linearly polarized laser pulses at fluences below the ablation threshold. These irradiation conditions restructure the surface according to an inhomogeneous intensity distribution, which is the result of an interference process between the incident beam and the scattered wave generated by the surface roughness at the start of irradiation. After this study we decided that further investigations need to be addressed regarding the effect of LIPSS on cavitation dynamics, particularly due to surface tension changes, aerophobicity and a possible change in the surface hardness of metallic material. Figure 4.1d shows the growth, collapse, and rebound of a cavitation bubble close to and stainless-steel substrate without and with LIPSS, respectively. When the nucleation is produced close to LIPSS, the bubble tends to growth further in the direction parallel to the surface, producing an asymmetric expansion and delaying the collapse time. Afterwards the consequent multiple rebounds and collapses occur away from the LIPPS, while in the flat sample they remain attached to the surface. Currently we are studying the same bubble dynamics on stainless steel but changing the surface tension to understand the effects of interfacial tension between bubble and surface.